Design and innovation in 3D printing have revolutionised the manufacturing industry by allowing for the creation of complex and customised objects with ease. This technology has opened up a world of possibilities, enabling designers and engineers to bring their ideas to life in ways that were previously unimaginable. With 3D printing, intricate and intricate designs can be produced with precision and accuracy, leading to improved product quality and functionality. Additionally, the ability to rapidly prototype and iterate designs has significantly reduced the time and cost associated with traditional manufacturing processes. As a result, 3D printing has become a powerful tool for innovation, enabling companies to stay competitive in an ever-evolving market.

In this post, we'll explore the fascinating impact of 3D printing on design innovation, and how 3D printing fuels creativity, customisation, and advancements in the design world.

1. Customisation: Easily modify designs for specific requirements or preferences

Many people appreciate the ability to customise designs to meet their specific requirements or preferences. Whether it's a piece of clothing, a piece of furniture, or even a digital interface, customisation allows individuals to have a unique and personalised experience. It gives them the freedom to choose colours, patterns, sizes, and other elements that resonate with their individual style and taste. Customisation not only enhances the overall satisfaction of the user but also adds a sense of ownership and identity to the product. With the option to easily modify designs, many people can now have products that truly reflect their personality and meet their specific needs.

2. Cost-effective prototyping for efficient design refinement.

3D printing enables quick and cost-effective prototyping, allowing designers to iterate and refine their designs more efficiently before moving to mass production.

Cost-effective prototyping is a crucial step in the design refinement process as it allows designers to test and evaluate their ideas before moving forward with production. By utilising affordable materials and techniques, designers can quickly create prototypes that accurately represent their vision while minimising costs. This enables them to identify any flaws or areas for improvement early on, leading to more efficient design iterations and ultimately a higher quality end product. Additionally, cost-effective prototyping allows designers to explore different design options and make informed decisions based on tangible prototypes, resulting in a more refined and successful final design.

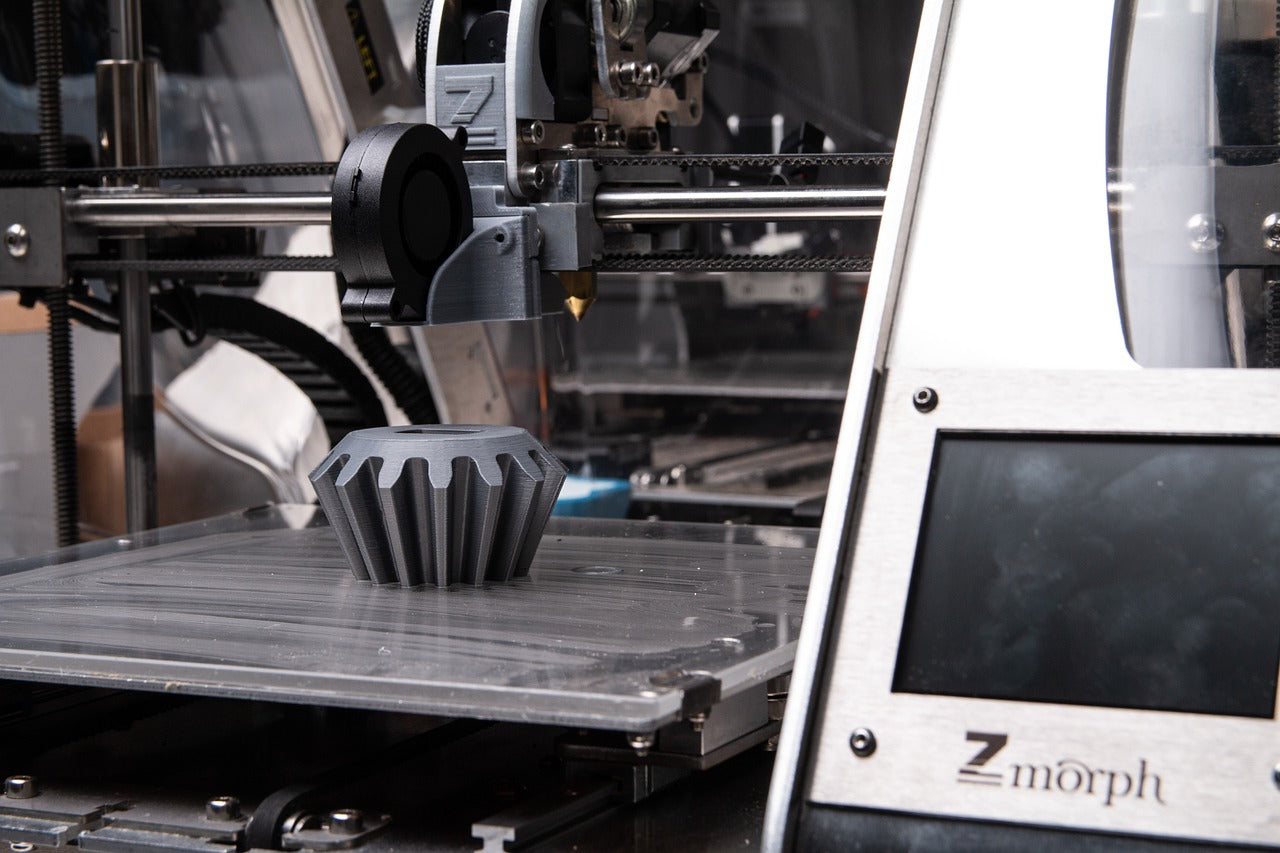

3. Intricate and unique designs with complex geometries.

Unlike traditional manufacturing methods, 3D printing can produce intricate and complex geometries that would be difficult or impossible to achieve using other techniques.

The input of intricate and unique designs with complex geometries leads to a visually stunning and captivating output. These designs are characterised by their intricate details and intricate patterns, which are carefully crafted to create a sense of depth and dimension. The complex geometries add an element of sophistication and elegance to the overall design, making it truly one-of-a-kind. Whether it's in architecture, fashion, or art, these intricate and unique designs with complex geometries never fail to leave a lasting impression on those who encounter them.

4. Versatile material options for innovative product creation

Nowadays, 3D printing offers a wide range of materials to choose from, including plastics, metals, ceramics, and even food-grade materials. This versatility allows designers to experiment with different materials and create innovative products with specific properties.

In today's rapidly evolving market, the demand for innovative products is higher than ever. To meet this demand, manufacturers are constantly seeking versatile material options that can be used to create unique and cutting-edge products. These materials need to be able to adapt to various design requirements, while also offering durability, flexibility, and aesthetic appeal. From advanced polymers and composites to sustainable and eco-friendly alternatives, the range of material options available is vast. By utilising these versatile materials, manufacturers can push the boundaries of product design and create innovative solutions that cater to the ever-changing needs and preferences of consumers.

5. Sustainability and Waste reduction through precise material usage

3D printing can contribute to sustainable design practices by reducing waste. It allows for precise material usage, minimising the amount of material needed for production, and enabling the recycling of unused or failed prints.

By utilising additive manufacturing techniques, this 3D printing allows for the creation of complex objects layer by layer, minimising material waste. Unlike traditional manufacturing methods that often result in excess material being discarded, 3D printing enables the production of customised products with only the necessary amount of material. This not only reduces waste but also promotes sustainability by conserving resources and minimising environmental impact. With 3D printing, the future of manufacturing is not only efficient but also environmentally conscious.

6. Design optimisation for innovative, purpose-driven solutions

With 3D printing, designers can optimise their designs for specific purposes, such as lightweight structures, improved functionality, or enhanced performance. This optimisation can lead to innovative solutions that were previously unattainable.

As the design process is refined, optimisation techniques can identify areas of improvement and streamline the development of products, systems, or processes. This not only leads to more efficient and cost-effective solutions but also encourages creativity and out-of-the-box thinking. Focusing on the end goal and continuously iterating and refining the design, design optimisation enables designers to create solutions that are not only aesthetically pleasing but also highly functional and tailored to meet specific needs and objectives.

7. Unrestricted design possibilities with 3D printing

3D printing eliminates many of the constraints imposed by traditional manufacturing methods, such as the need for molds or tooling. This freedom allows designers to explore unconventional shapes, structures, and forms, pushing the boundaries of design and innovation.

With the advent of 3D printing, designers now have unrestricted possibilities when it comes to creating and bringing their ideas to life. This revolutionary technology allows for the production of complex and intricate designs that were previously impossible or extremely difficult to achieve using traditional manufacturing methods. From intricate jewelry pieces to functional prototypes, 3D printing opens up a world of creativity and innovation. Designers can now experiment with different shapes, textures, and materials, pushing the boundaries of what is possible in the design world. This newfound freedom allows for the creation of unique and personalised products that cater to individual needs and preferences. With unrestricted design possibilities, 3D printing is revolutionising the way we think about and approach design.

8. Democratisation of design and manufacturing through accessibility.

3D printing has become increasingly accessible to individuals and small businesses, democratising the design and manufacturing process. This accessibility fosters a culture of innovation, as more people can experiment, create, and share their designs, leading to a broader range of innovative products.

Using 3D printing and other accessible technologies, individuals and small businesses now have the ability to design and manufacture their own products without the need for expensive equipment or specialised knowledge. As the use of 3D printers grows, the playing field has levelled, allowing for greater innovation and creativity to flourish. Overall, the democratisation of design and manufacturing through accessibility has opened up new opportunities and possibilities for individuals and communities, fostering a more inclusive and diverse marketplace.

Overall, 3D printing offers numerous advantages in the design and manufacturing process. It allows for customisation, rapid prototyping, the creation of complex geometries, and a wide variety of materials to choose from. Additionally, it promotes sustainability, design optimisation, design freedom, and accessibility. These benefits open up new possibilities for innovation and unique designs, while also reducing waste and democratising the design process.

As 3D printing continues to advance and become more accessible, it is important for individuals and businesses to embrace this technology and explore its potential. By doing so, we can foster a culture of innovation and create a broader range of innovative products.

Ready to start printing? Get started by checking out our range of 3D printers.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.