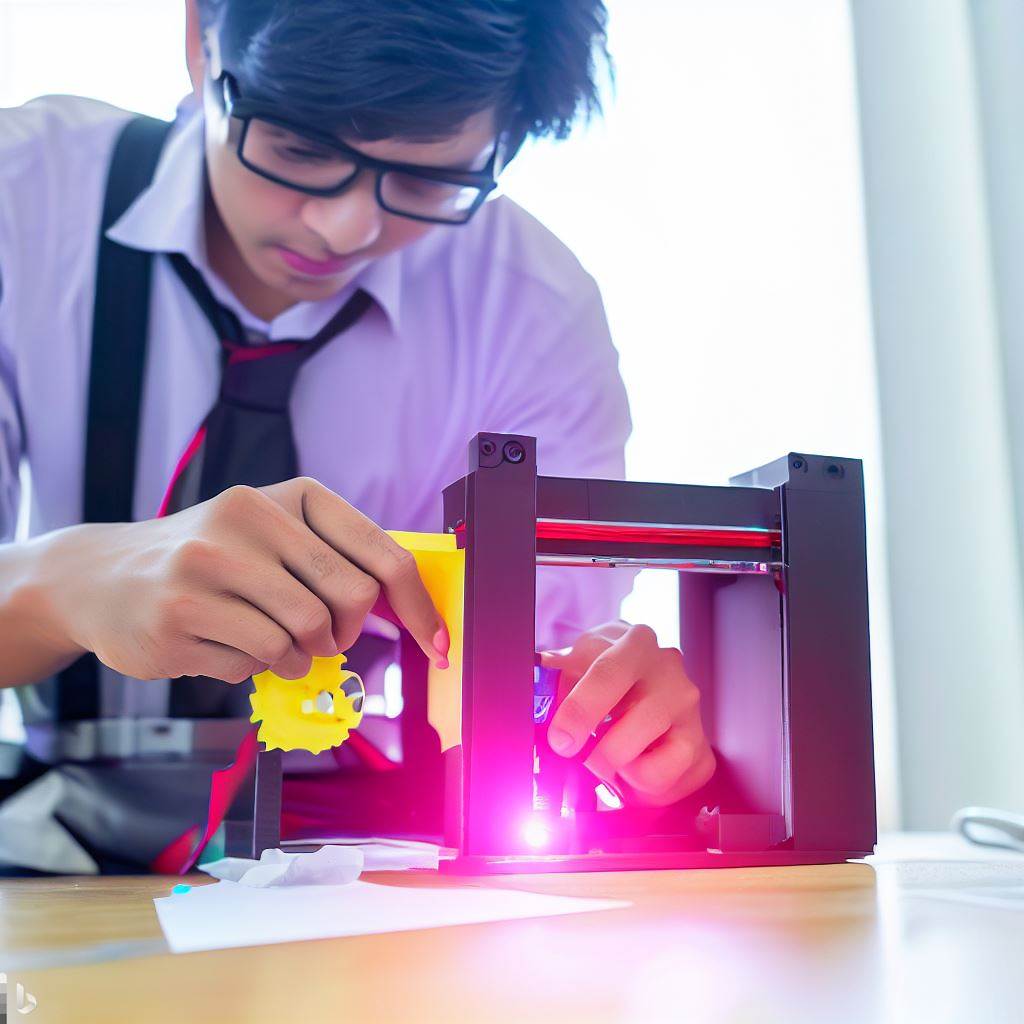

3D printing has emerged as a revolutionary technology that has the potential to transform various industries. This innovative process involves creating three-dimensional objects by layering materials based on a digital design. While 3D printing offers numerous benefits such as increased customization, reduced waste, and improved efficiency, its impact on sustainability is a topic of great interest.

Can 3D printing be sustainable?

In addition to reshaping industries, 3D printing contributes to a more environmentally friendly and resource-efficient method of production. Here are a few ways that 3D printing is promoting eco-friendly practices and driving a more sustainable future.

Reduced waste

3D printing allows for precise and on-demand manufacturing, which significantly reduces material waste compared to traditional manufacturing methods. It only uses the exact amount of material needed for each product, minimising excess waste.

By producing goods only when they are needed and in exact quantities, companies are able to reduce excess inventory and eliminate the need for large-scale production runs. This not only reduces the amount of waste generated but also saves resources and energy that would have been used in the traditional manufacturing process. Overall, the adoption of this approach by many companies is a significant step towards a more sustainable and efficient future.

Less energy, lower emissions

3D printing consumes less energy compared to conventional manufacturing processes. It eliminates the need for large-scale factories and transportation of goods, resulting in lower energy consumption and reduced carbon emissions.

The implementation of sustainable practices and technologies has led to significant improvements in energy efficiency, reduced reliance on traditional factories, and lower emissions. With the use of renewable energy sources and energy-saving measures, industries have been able to minimise their energy consumption. A shift towards decentralised production methods, such as 3D printing and local manufacturing, can also reduce the need for large-scale factories, resulting in decreased emissions from transportation and production processes. These advancements in sustainable practices have not only contributed to a greener and cleaner environment but have also paved the way for a more sustainable and resilient future.

Extended product lifespan through repair and maintenance

3D printing allows for the creation of replacement parts, making it easier to repair and maintain products. This extends the lifespan of items, reducing the need for new purchases. With the ability to create intricate and customized parts, 3D printing allows for the repair of items that would have otherwise been discarded. This technology enables individuals and businesses to easily replace broken or worn-out components, reducing waste and promoting sustainability. By embracing 3D printing, we can now breathe new life into products, ensuring their longevity and minimising our impact on the environment.

Recycling waste materials for sustainable production

Materials used for 3D printing can include recycled materials such as plastic waste to create new products. This promotes a circular economy by reducing the demand for virgin materials and diverting waste from landfills. By reusing and repurposing waste materials, we can reduce the amount of waste that ends up in landfills and reduce the need for extracting and processing new raw materials. This not only conserves natural resources but also helps to reduce pollution and greenhouse gas emissions associated with the production of new materials. Additionally, recycling waste materials can create new economic opportunities and jobs in the recycling industry, contributing to a more circular and sustainable economy. Overall, recycling waste materials is a win-win solution that benefits both the environment and the economy.

On-demand production reduces inventory and storage impact

On-demand production is a manufacturing approach that focuses on producing goods only when there is a demand for them. This method eliminates the need for large inventories and storage spaces, as products are not produced in excess and stored for long periods of time. This decreases the environmental impact associated with excess inventory, such as energy consumption for storage facilities and the risk of unsold products ending up as waste. This approach also allows for greater flexibility in meeting customer demands, as products can be quickly produced and delivered in response to specific orders.

In conclusion, 3D printing offers numerous environmental benefits that contribute to a more sustainable future. It reduces waste by using only the necessary amount of materials and enables localised production, reducing the need for long-distance transportation. Additionally, 3D printing allows for customisation and personalisation, reducing the likelihood of products being discarded due to poor fit or functionality. It also promotes repair and maintenance, extending the lifespan of items and reducing the need for new purchases. Furthermore, 3D printing can utilize recycled materials and reduces water consumption and the need for large inventories and storage spaces. To harness the full potential of 3D printing for sustainability, individuals and businesses should embrace this technology and explore its applications in various industries. By doing so, we can contribute to a more efficient and environmentally friendly manufacturing process.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.