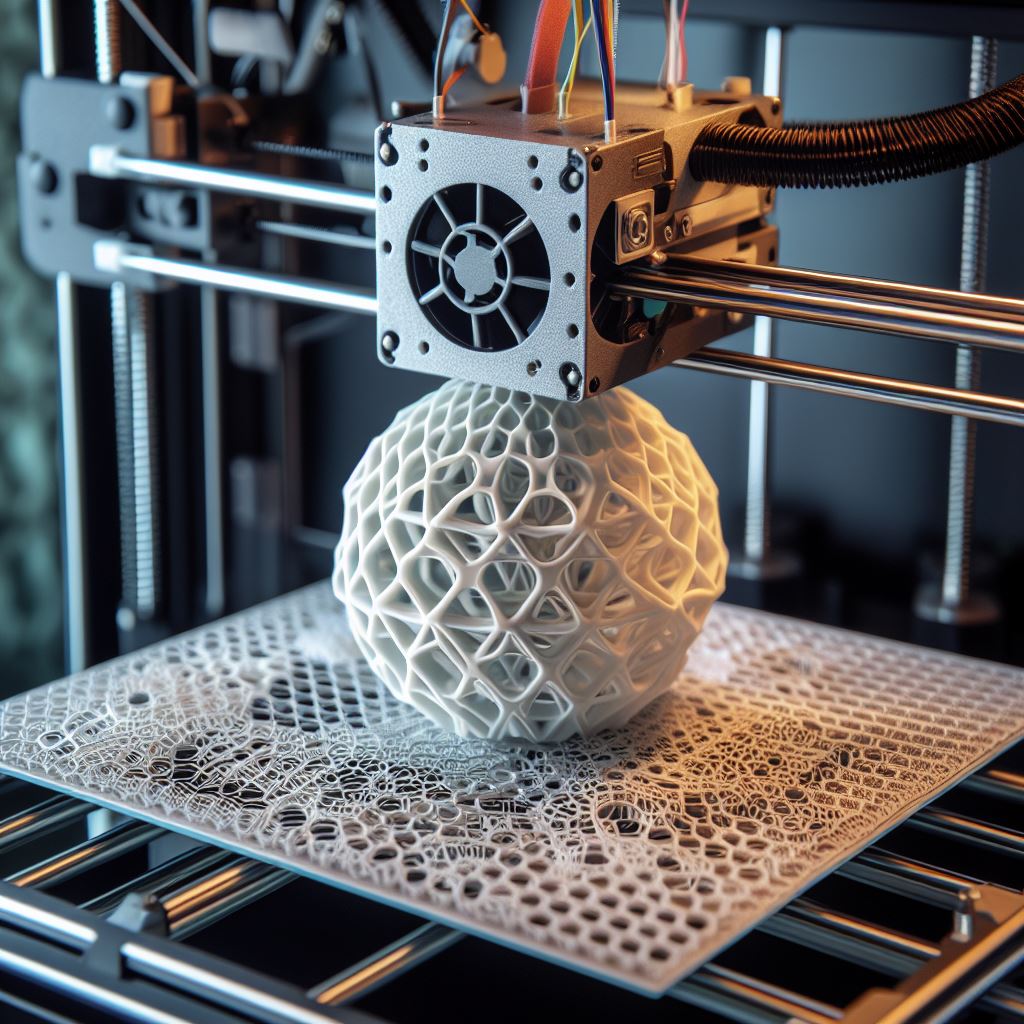

3D printing, also known as additive manufacturing, is a revolutionary technology that is transforming various industries. 3D printing allows you to create three-dimensional objects from a digital file by adding layer upon layer of material. But how does 3D printing actually work? Let's dive into the fascinating process behind this cutting-edge technology.

How Does 3D Printing actually work?

The process involves the layer-by-layer deposition of material, typically in the form of liquid resin or powdered material, which is then solidified or fused together to form the desired object. This innovative technique has gained immense popularity in various industries, including manufacturing, healthcare, and aerospace, due to its ability to produce complex and customized objects with high precision and efficiency. Understanding how 3D printing works is crucial to harnessing its full potential and exploring the endless possibilities it offers.

Here is a step-by-step process of how 3D printing works.

1. Designing the Object

The first step in 3D printing is to create a digital model of the object you want to print. This can be done using computer-aided design (CAD) software or by scanning an existing object using a 3D scanner. The digital model serves as a blueprint for the 3D printer to follow.

2. Slicing the Model

Once the digital model is ready, it needs to be sliced into thin layers. This is done using slicing software, which divides the model into hundreds or thousands of horizontal layers, each with a specific thickness. The slicing software also generates instructions for the 3D printer on how to build each layer.

3. Preparing your 3D Printer

Before printing can begin, the 3D printer needs to be prepared. This involves ensuring that the print bed is clean and level, and that the printer has the appropriate filament or material loaded. The filament is typically made of plastic, but other materials such as metal, resin, or even food can also be used.

4. Printing the Object

With the printer prepared, the actual printing process can begin. The 3D printer starts by heating the filament to its melting point. It then extrudes the molten material through a nozzle, which moves in a precise pattern dictated by the instructions from the slicing software. The nozzle deposits the material layer by layer, gradually building up the object.

5. Cooling and Finishing

Once the object is fully printed, it needs to cool and solidify. This can be done naturally or with the help of fans or other cooling mechanisms. After cooling, any support structures that were printed to hold up overhanging parts of the object are removed. The object may also undergo additional post-processing steps, such as sanding, painting, or polishing, to achieve the desired finish.

6. Quality Control

Before the printed object is considered complete, it undergoes a thorough quality control process. This may involve inspecting the object for any defects, measuring its dimensions to ensure accuracy, and testing its functionality, if applicable. Any necessary adjustments or refinements can be made at this stage.

7. Applications of 3D Printing

3D printing has a wide range of applications across various industries. It is used in manufacturing to create prototypes, custom parts, and even finished products. In healthcare, 3D printing is used to create medical implants, prosthetics, and anatomical models for surgical planning. It is also used in architecture, automotive, aerospace, and many other fields.

As technology continues to advance, 3D printing is becoming more accessible and affordable, opening up new possibilities for innovation and creativity. Understanding how 3D printing works is the first step towards harnessing its potential and exploring the exciting world of additive manufacturing.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.