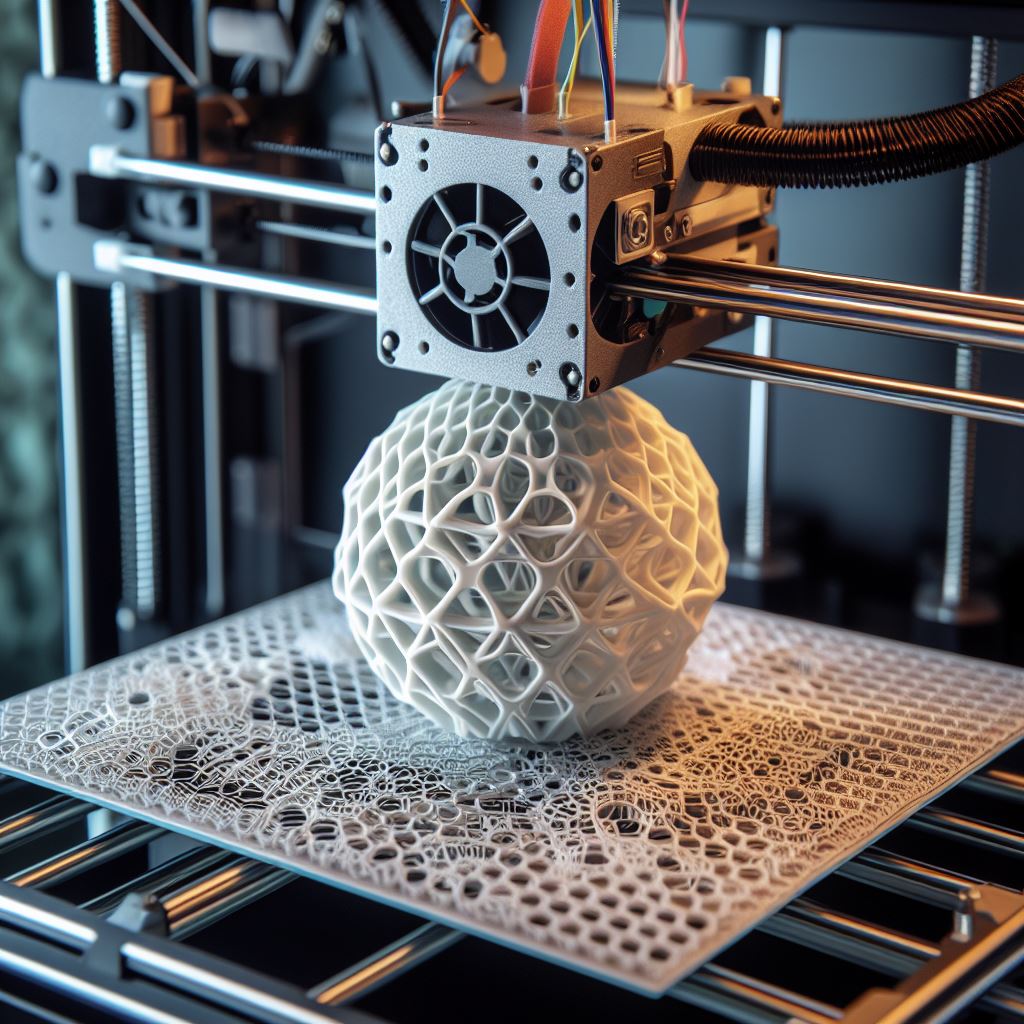

Efficiency is a crucial factor in the success of any dental lab. With the advancements in technology, dental labs are now able to streamline their workflow and improve productivity through the use of 3D-printing technology. 3D-printing efficiency refers to the ability of dental labs to produce high-quality dental restorations in a shorter amount of time, with fewer resources and minimal manual labor.

How Does 3D-Printing Improve Efficiency?

Traditional methods of dental restoration production involve multiple time-consuming steps, such as manual waxing, casting, and finishing. These processes not only require skilled technicians but also increase the chances of human error. 3D-printing technology eliminates many of these manual steps, allowing dental labs to produce restorations more efficiently.

By using 3D-printing technology, dental labs can create digital models of patients' teeth and directly print them using biocompatible materials. This eliminates the need for manual waxing and casting, reducing the production time significantly. Additionally, 3D-printing technology ensures a higher level of precision and accuracy, resulting in better-fitting restorations and fewer remakes.

What Are the Benefits of 3D-Printing Efficiency for Dental Labs?

1. Time Savings: 3D-printing technology enables dental labs to produce restorations in a fraction of the time compared to traditional methods. This allows for faster turnaround times, which is beneficial for both the dental lab and the patients.

2. Cost Savings: By reducing the need for manual labor and minimizing material waste, 3D-printing technology helps dental labs save on production costs. This cost-effectiveness can be passed on to the patients, making dental treatments more affordable.

3. Improved Quality: 3D-printing technology ensures a higher level of precision and accuracy in dental restorations. This leads to better-fitting restorations, improved patient satisfaction, and fewer remakes, saving both time and resources.

How Can Dental Labs Maximise 3D-Printing Efficiency?

1. Invest in High-Quality 3D Printers: Dental labs should invest in reliable and high-quality 3D printers that can handle the specific requirements of dental restorations. This ensures consistent and accurate results, minimizing the chances of errors and remakes.

2. Optimize Workflow: Dental labs should analyze their workflow and identify areas where 3D-printing technology can be integrated to maximize efficiency. By automating repetitive tasks and minimizing manual labor, labs can save time and resources.

3. Stay Updated with Technology: The field of 3D-printing is constantly evolving, with new materials and techniques being introduced regularly. Dental labs should stay updated with the latest advancements in 3D-printing technology to take full advantage of its efficiency benefits.

Efficient workflow: Digital design and direct printing

Efficient workflow in digital design and direct printing has revolutionized the way businesses and individuals create and produce printed materials. With the advancements in technology, designers can now seamlessly transfer their digital designs directly to the printing press, eliminating the need for traditional methods such as film and plates. This not only saves time and resources but also allows for greater accuracy and flexibility in the design process. Additionally, direct printing eliminates the need for intermediate steps, resulting in faster turnaround times and reduced costs. Overall, the integration of digital design and direct printing has greatly improved efficiency in the printing industry, enabling businesses to produce high-quality printed materials in a more streamlined and cost-effective manner.

Accelerates dental research and development, fostering innovation.

Accelerating dental research and development is crucial for fostering innovation in the field. By providing a platform for researchers and scientists to collaborate and share their findings, new breakthroughs and advancements can be made in dental technology and treatments. This not only improves the overall quality of dental care but also enhances patient outcomes and experiences. Additionally, accelerating research and development in dentistry allows for the discovery of new materials, techniques, and technologies that can revolutionize the way dental procedures are performed. Ultimately, this leads to improved oral health outcomes for individuals and contributes to the overall advancement of dental science.

3D-printing technology has revolutionized the dental industry, providing dental labs with the opportunity to improve efficiency and productivity. By embracing this technology and implementing it effectively, dental labs can save time, reduce costs, and deliver high-quality dental restorations to their patients. Maximising 3D-printing efficiency is not only beneficial for the dental lab but also for the overall patient experience.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.